"JPEx": Japan Explosion Protection

to be instead of former TIIS.

Access to the global market

The certification contributes to expanding the market for explosion-proof products to the world.

・EU, international market: ATEX certification

・Country-specific standards: IECEx certification-> JPEx & each country’s certification

Increased safety and reduced risk enable innovative design and manufacturing. Obtaining certification is one option to show the high quality of the product. With one-stop service proposed by us, we can beat today’s society and accelerate the global expansion of products.

The certification contributes to expanding the market for explosion-proof products to the world.

・EU, international market: ATEX certification

・Country-specific standards: IECEx certification-> JPEx & each country’s certification

Increased safety and reduced risk enable innovative design and manufacturing. Obtaining certification is one option to show the high quality of the product. With one-stop service proposed by us, we can beat today’s society and accelerate the global expansion of products.

Taking IECEx-TR, which conforms to the explosion-proof standards of 36 IECEx member countries, is a prerequisite for global products.

One-stop service for applying all at once, for explosion proof certificate

How about considering a batch application for certificate of explosion protection in each country with the one-stop service proposed by us.

How about considering a batch application for certificate of explosion protection in each country with the one-stop service proposed by us.

- For domestic products, it is possible to obtain IECEx & ATEX at the same time by applying for Japan Explosion Protection (JPEx) in the internationally harmonized technical guidelines.

- For global products, by attaching ExTR at application, it is possible to apply for Japanese explosion protection without testing with the actual machine.

- For other countries explosion-proof applications, please contact us.

Basic matters concerning “explosion-proof electrical equipment.”

Regulation by law in Japan

・Industrial Safety and Health Act

・Occupational Safety and Health Enforcement Order

・Electrical Machinery Explosion-proof Structural Standards (Ministry of Labor Notification No. 16, 1969)

・Ordinance for Examination of Machines, etc. (Ministry of Labor Ordinance No. 45, 1972)

Regulation by law in Japan

・Industrial Safety and Health Act

・Occupational Safety and Health Enforcement Order

・Electrical Machinery Explosion-proof Structural Standards (Ministry of Labor Notification No. 16, 1969)

・Ordinance for Examination of Machines, etc. (Ministry of Labor Ordinance No. 45, 1972)

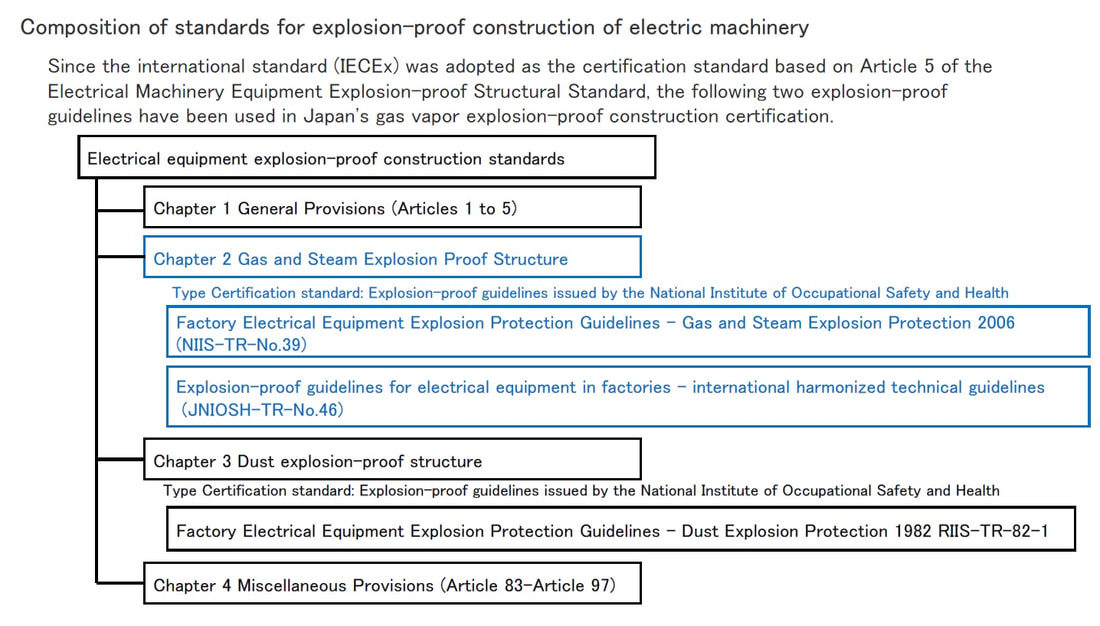

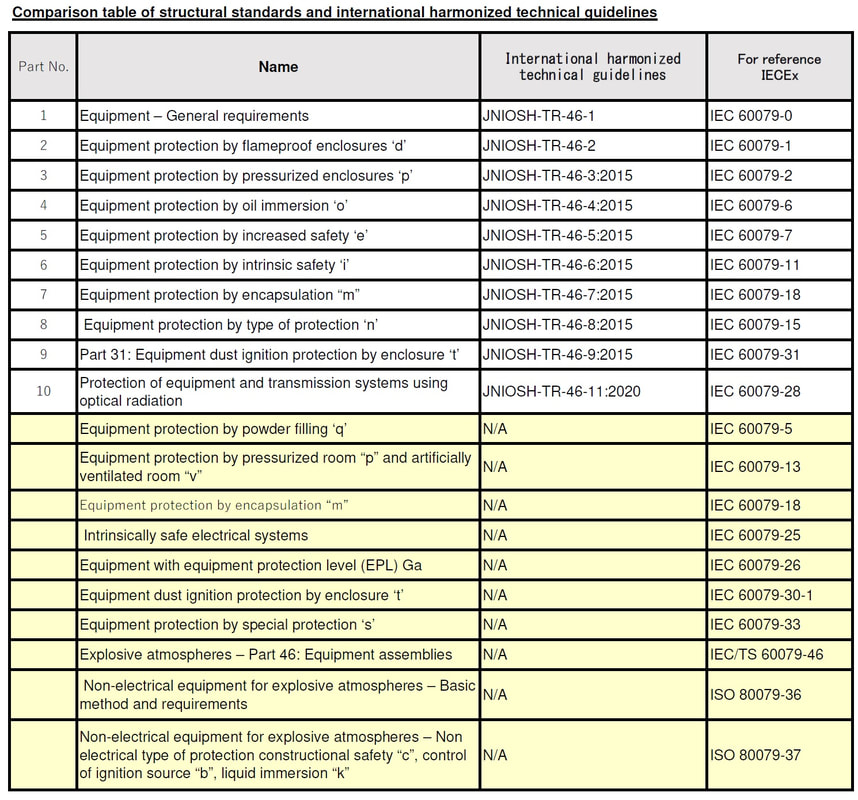

Configuration of explosion-proof construction standards for electric machinery

Based on Article 5 of the explosion-proof structure standards for electrical machinery and equipment, the international standard (IECEx) has been adopted as the standard for certification. And the following two explosion-proof guidelines are used in the certification of gas vapor explosion-proof structures in Japan.

Based on Article 5 of the explosion-proof structure standards for electrical machinery and equipment, the international standard (IECEx) has been adopted as the standard for certification. And the following two explosion-proof guidelines are used in the certification of gas vapor explosion-proof structures in Japan.

Based on the fact that the IECEx Equipment Certification Scheme stipulates that a new type approval shall be issued for the current edition or the previous edition (one previous edition) of the standard, the same shall apply to the Internationally Harmonized Technical Guidelines.

When applying for internationally harmonized technical guidelines using ExTR

Excerpt from “KIHATSU” issued by the Labor Standards Bureau, Ministry of Health, Labor and Welfare.

Application with ExTR attached to the application form: Article 6, Paragraph 1, Item 4 of the Appraisal Regulations “Document stating the results of tests conducted in advance on the type of machine, etc.”

When applying for internationally harmonized technical guidelines using ExTR

Excerpt from “KIHATSU” issued by the Labor Standards Bureau, Ministry of Health, Labor and Welfare.

Application with ExTR attached to the application form: Article 6, Paragraph 1, Item 4 of the Appraisal Regulations “Document stating the results of tests conducted in advance on the type of machine, etc.”

ExTR issued by ExCB under IECEx (with the date of issuance within the valid period of ExCB certification) is attached, and if the following requirements (1) and (2) are confirmed, the report shall be submitted as a It may be treated as a “document stating the results of tests conducted in advance regarding If there is an error or unclear part in the ExTR, the relevant part shall be inspected using the actual equipment.

(1) The attached ExTR must be for the model for which the application was made.

(2) The attached ExTR must be properly issued by ExCB based on IECEx.

(1) The attached ExTR must be for the model for which the application was made.

(2) The attached ExTR must be properly issued by ExCB based on IECEx.

Article 6. Attempting to receive a new application (hereinafter referred to as “new certification”) for the certification pursuant to the provisions of Article 44-2, paragraph 1 or 2 of the Act (hereinafter referred to as “type certification”) In this case, the person who conducts the type examination by attaching the following drawings and documents to the new examination application form (Form No. 6) for each type for which the new examination is to be performed (hereinafter referred to as the “type examination operator”). ) must be submitted to

1. Structural drawing of the machine, etc. of the relevant type and, in the case of a machine, etc. with electrical circuits, the relevant circuit diagram

2. Instructions on the performance of the machine, etc. and instructions on how to handle the machine, etc.

3 Document stating the following items related to the machine, etc.

a) Outline of the equipment that manufactures and inspects the machine, etc.

b) Person in charge of working on the machine, etc.

c) Inspection organization for the machine, etc.

d) Regulations for inspection of the machine, etc.

4. A document stating the results of tests conducted in advance on the machine of the model concerned

5. For machines, etc. listed in Article 14-2, item 8 of the Cabinet Order, a specification in Form 7

1. Structural drawing of the machine, etc. of the relevant type and, in the case of a machine, etc. with electrical circuits, the relevant circuit diagram

2. Instructions on the performance of the machine, etc. and instructions on how to handle the machine, etc.

3 Document stating the following items related to the machine, etc.

a) Outline of the equipment that manufactures and inspects the machine, etc.

b) Person in charge of working on the machine, etc.

c) Inspection organization for the machine, etc.

d) Regulations for inspection of the machine, etc.

4. A document stating the results of tests conducted in advance on the machine of the model concerned

5. For machines, etc. listed in Article 14-2, item 8 of the Cabinet Order, a specification in Form 7

Equipment protection level (EPL): The equipment protection level (hereinafter referred to as “EPL”), which indicates the degree to which explosion-proof equipment does not become an ignition source or an ignition source, including when it is malfunctioning. It was introduced from the International Harmonized Explosion Protection Guidelines 2015.

Handling of Ex components, etc.:

a) Ex components, Ex cable glands, Ex screw adapters, and Ex closing parts (hereinafter referred to as “Ex components, etc.”) are not subject to the type examination based on the law as individual units, but they are explosion-proof. It is necessary to maintain the explosion-proof structure of the equipment and is used by being incorporated into the explosion-proof equipment.

b) In the case where a registered type examination body conducts an examination according to the Internationally Harmonized Explosion Protection Guideline 2020, the said type examination body shall provide certificates, etc. related to Ex components, etc. is issued, and if you have drawings, test data, etc. related to the Ex-component, etc., you may use them for testing until the certificate, etc. expires.

Here, certificates, etc. related to Ex components, etc. are limited to those based on the same standards as the International Harmonized Explosion Protection Guidelines 2020.

a) Ex components, Ex cable glands, Ex screw adapters, and Ex closing parts (hereinafter referred to as “Ex components, etc.”) are not subject to the type examination based on the law as individual units, but they are explosion-proof. It is necessary to maintain the explosion-proof structure of the equipment and is used by being incorporated into the explosion-proof equipment.

b) In the case where a registered type examination body conducts an examination according to the Internationally Harmonized Explosion Protection Guideline 2020, the said type examination body shall provide certificates, etc. related to Ex components, etc. is issued, and if you have drawings, test data, etc. related to the Ex-component, etc., you may use them for testing until the certificate, etc. expires.

Here, certificates, etc. related to Ex components, etc. are limited to those based on the same standards as the International Harmonized Explosion Protection Guidelines 2020.

Routine test: The “routine test” newly included in the Internationally Harmonized Explosion-Proof Guidelines 2015 requires that when applying for a new test, the machine, etc. test regulations (1972 Ministry of Labor Ordinance No. 45; Article 6 The type approval agency shall confirm the type of test, implementation method, etc. based on the document submitted by the applicant based on the provisions of paragraph 1, item 3, d). In addition, the same shall apply to renewal certification based on the provisions of Article 11 of the Certification Regulations.

Scope of electrical equipment to which Article 280 of the Safety and Health Regulations does not apply (simple equipment)

According to IEC standards, electrical equipment whose maximum rated voltage, etc. Even if it is used in a place where dangerous concentrations may be reached, it must not become an ignition source or a source of ignition, and Articles 280 to 282 of the Industrial Safety and Health Regulations shall not apply. However, this shall not apply when there is a risk that the rated voltage, etc. of the circuit of the electrical equipment may exceed the value of each category in the following table by connecting the electrical equipment to other electrical equipment.

・Rated voltage: 1.5 volts (1.2 V in International Harmonized Technical Guidelines 2008)

・Rated current: 0.1 amperes

・Rated power: 25 milliwatts

・Passive components (switches, resistors, etc.)

・Energy storage sources (equipment including capacitors, inductors, etc.)

・Energy source (thermocouple, photocell, etc.)

According to IEC standards, electrical equipment whose maximum rated voltage, etc. Even if it is used in a place where dangerous concentrations may be reached, it must not become an ignition source or a source of ignition, and Articles 280 to 282 of the Industrial Safety and Health Regulations shall not apply. However, this shall not apply when there is a risk that the rated voltage, etc. of the circuit of the electrical equipment may exceed the value of each category in the following table by connecting the electrical equipment to other electrical equipment.

・Rated voltage: 1.5 volts (1.2 V in International Harmonized Technical Guidelines 2008)

・Rated current: 0.1 amperes

・Rated power: 25 milliwatts

・Passive components (switches, resistors, etc.)

・Energy storage sources (equipment including capacitors, inductors, etc.)

・Energy source (thermocouple, photocell, etc.)

Inverter motor: Flame-proof motors cannot be used unless they have passed the “explosion-proof test” in a one-to-one combination with an inverter by law. The use of inverters approved for combination by explosion proof certification is obligatory. It is obligatory to indicate on the combination nameplate the combination that has passed the “explosion proof test” in a one-to-one combination with the inverter. Moters of “type of protection “n” electrical apparatus” are not permitted to be combined with inverters.

Electric heater: An application that maintains explosion-proof performance for the entire system, including the interlock circuit and temperature control, is required.

Overview of manufacturing inspection equipment, etc.: Foreign products must meet the manufacturer’s qualification requirements (Article 6, Paragraph 1, Item 3 of the Appraisal Regulations) with a certificate of conformity (IECExCoC) issued by a certification body (ExCB). I assume.

Article 6, Paragraph 1, Item 3 of the Appraisal Rules

3. A document stating the following items related to the machine, etc.

A. Outline of the equipment that manufactures and inspects the machine, etc.

B. The person in charge of the work of the machine, etc.

C. Inspection organization for the machine, etc.

D. Regulations for inspection of the machine, etc.

Note that Factory audits are not required in Japan’s explosion-proof certification system. You will submit a summary of manufacturing inspection equipment at the time of application and at the time of renewal, and we will examine the documents.

Test/Evaluation: Japan’s certification system allows manufacturers to confirm the suitability of designs and conduct evaluation tests (first-party certification/In-house certification). It is possible to submit this report to the certification body as “results of tests conducted in advance”. The submitted “preliminary test results” and the test (verification test) conducted by the certification body are evaluated, and if conformity to the standard is confirmed, the certification body issues a type approval certificate.

Fast Track Process: IECEx have a rule below.

“ExCB organizations accept ExTRs issued by foreign ExCBs, conduct additional tests and evaluations for parts that do not comply with their own standards, and issue a certificate of conformity that are valid in their own country.”

Electric heater: An application that maintains explosion-proof performance for the entire system, including the interlock circuit and temperature control, is required.

Overview of manufacturing inspection equipment, etc.: Foreign products must meet the manufacturer’s qualification requirements (Article 6, Paragraph 1, Item 3 of the Appraisal Regulations) with a certificate of conformity (IECExCoC) issued by a certification body (ExCB). I assume.

Article 6, Paragraph 1, Item 3 of the Appraisal Rules

3. A document stating the following items related to the machine, etc.

A. Outline of the equipment that manufactures and inspects the machine, etc.

B. The person in charge of the work of the machine, etc.

C. Inspection organization for the machine, etc.

D. Regulations for inspection of the machine, etc.

Note that Factory audits are not required in Japan’s explosion-proof certification system. You will submit a summary of manufacturing inspection equipment at the time of application and at the time of renewal, and we will examine the documents.

Test/Evaluation: Japan’s certification system allows manufacturers to confirm the suitability of designs and conduct evaluation tests (first-party certification/In-house certification). It is possible to submit this report to the certification body as “results of tests conducted in advance”. The submitted “preliminary test results” and the test (verification test) conducted by the certification body are evaluated, and if conformity to the standard is confirmed, the certification body issues a type approval certificate.

Fast Track Process: IECEx have a rule below.

“ExCB organizations accept ExTRs issued by foreign ExCBs, conduct additional tests and evaluations for parts that do not comply with their own standards, and issue a certificate of conformity that are valid in their own country.”